Sustainable Building Materials: Building the Generation Responsibly

The construction industry across the world is experiencing a defining moment of change. Climate change, rising global energy demands, and the pressures of rapid urbanization have placed the spotlight firmly on sustainable building materials we use to build our homes, offices, and cities.

What was once a matter of choice has now become a necessity. These innovative materials are essential if we have to create infrastructure that is both climate-resilient and energy-efficient.

Every brick, tile, or block that goes into construction has a story, one that impacts not just the appearance of a building but also its long-term performance, durability, and environmental footprint.

Conventional methods often consume vast amounts of energy, deplete natural resources, and leave behind a heavy carbon trail. In contrast, sustainable alternatives offer smarter, cleaner, and more efficient pathways toward progress.

From walls and façades to roofs and flooring, the selection of materials determines how well a structure can insulate, conserve energy, withstand time, and reduce greenhouse gas emissions. That is why architects, engineers, and developers worldwide are increasingly turning to eco-friendly, recyclable, and high-performing options.

What Makes a Material Sustainable?

A sustainable building material goes beyond just being “eco-friendly.” It is one that reduces environmental harm throughout its lifecycle, right from production and usage to disposal, while still delivering durability, strength, and comfort.

In modern construction, sustainability means creating structures that serve people efficiently today without compromising the needs of future generations. Key characteristics of sustainable materials include:

- Low Carbon Footprint: Sustainable materials are manufactured using processes that emit significantly less CO₂ compared to conventional options. This reduces the overall greenhouse gas emissions from construction and directly supports climate-friendly development.

- Energy Efficiency: Building materials with natural insulating properties help maintain indoor comfort, lowering the reliance on air-conditioning or artificial heating.

- Durability & Longevity: A truly sustainable material is one that stands the test of time. If a product resists weathering, wear, and environmental stress, it reduces the need for frequent repairs or replacements, saving resources, costs, and energy in the long run.

- Recyclability & Natural Composition: Materials made from natural, non-toxic, and recyclable resources. At the end of their lifecycle, they can be safely reused, recycled, or returned to the earth with minimal waste generation, completing a healthy ecological cycle.

Traditional vs Sustainable Materials

Traditional building materials such as conventional bricks, cement, and steel have long been the backbone of construction. However, they are highly resource-intensive and often carry a heavy carbon footprint. In today’s world, where climate goals and energy efficiency are no longer optional, the industry is shifting toward sustainable alternatives through advanced eco-friendly construction technology.

To understand this shift, sustainable materials can broadly be grouped into two categories:

1. Natural Materials: Rooted in Ecology

Natural materials have been part of construction for centuries. They are eco-friendly, biodegradable, and naturally energy-efficient. Some key examples include:

- Wood: A renewable resource with excellent load-bearing capacity, often used for structural frameworks and interiors.

- Bamboo: Stronger than many types of steel in tensile strength, bamboo is fast-growing, lightweight, and highly sustainable.

- Straw: Commonly used for insulation and roofing, straw is affordable, biodegradable, and provides good thermal efficiency.

- Cork: Harvested from cork oak trees without harming them, cork is lightweight, insulating, and ideal for flooring and wall panels.

- Hempcrete: Made from hemp fibers and lime, it provides excellent insulation and breathability while locking in carbon.

- Rammed Earth: Created by compacting natural soil layers, it produces strong, durable walls with impressive thermal mass.

- Clay: Naturally abundant and versatile, clay is used in bricks, blocks, and plasters. It offers durability, thermal comfort, moisture regulation, and is 100% recyclable.

Among all these natural materials, clay stands out as the most reliable and time-tested option. Its abundance, versatility, and proven performance make it the backbone of countless structures around the world.

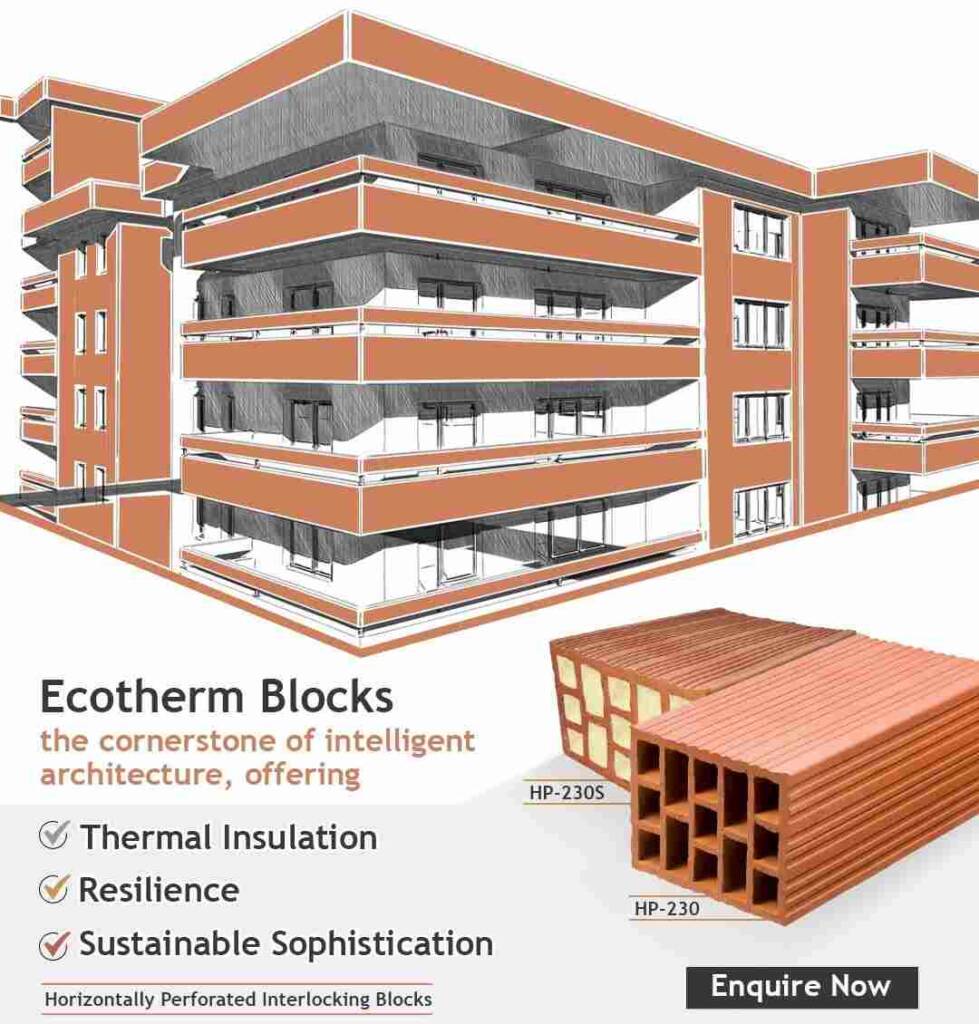

A prime example is Ecotherm Hollow Clay Blocks, made from abundant natural clay. These resource-efficient materials provide structural strength, natural thermal insulation, and recyclability. Their hollow structure reduces the need for artificial heating or cooling, lowering energy consumption and improving indoor comfort.

By rethinking clay as not just a traditional choice but a sustainable upgrade, Ecotherm shows how natural resources can meet modern demands.

2. Innovative Composites & Hybrids: Engineering the Future

This category includes advanced solutions like composites, self-healing materials, and hybrid systems that push the boundaries of construction technology. They deliver high strength, durability, and low carbon footprints, making them suitable for future-ready buildings through cutting-edge eco-friendly construction technology

While Ecotherm belongs to the natural family, its design innovation sets it apart. Its engineered hollow structure transforms clay into an advanced thermal solution, positioning it as a bridge between the natural and the innovative.

This unique blend of tradition and technology is exactly why Ecotherm has earned global recognition from the HCL Climaforce Fund, which honored it as “the most advanced sustainable thermal insulating clay product in the world.”

Global Recognition of Ecotherm in Sustainable Construction

Sustainability in construction is not only about creating eco-friendly materials, it is also about proving their value on the global stage. Innovation becomes truly powerful when it is validated beyond borders, and that is exactly what has happened with Ecotherm Hollow Clay Blocks.

We are proud to share that Ecotherm has been recognized by the HCL Climaforce Fund as “the most advanced sustainable thermal insulating clay product in the world.” This recognition is more than just an award, it is an international endorsement of our commitment to creating low-carbon, high-performance building materials that redefine modern construction.

By earning this distinction, Ecotherm now stands alongside a select group of innovations shaping the future of green buildings worldwide. It highlights how a material rooted in nature and refined through engineering can meet the highest sustainability standards and still deliver uncompromised performance.

For us, this milestone reinforces our long-standing mission: to provide building solutions that are eco-friendly, energy-efficient, and climate-resilient. It validates the belief we have carried since the beginning that India can not only contribute to global sustainability but also set new benchmarks in construction innovation.

Eco-Friendly Clay Hollow Blocks:

Among all sustainable building materials, clay blocks stand out as a timeless yet forward-looking choice. Made from natural clay, they are abundant, recyclable, and highly durable, firmly placing them within the Natural Materials category. But when engineered with advanced hollow designs, they also step into the realm of Innovative Composites, proving that tradition and technology can work hand in hand.

When we talk about sustainability, it’s not only about how we build today but also about how the materials we choose perform in the long run. Ecotherm stands out because it merges traditional wisdom with modern engineering, offering features that directly address the most pressing needs of eco-conscious construction through advanced eco-friendly construction technology.

Why Ecotherm Hollow Clay Blocks Are Sustainable?

a. Waste Reduction in Construction

Ecotherm’s modular and precision-engineered design minimises on-site cutting and breakage. Less waste means fewer landfill trips, cleaner sites, and significant cost savings during construction.

b. Lower Maintenance Over Building Life

Built to last, Ecotherm blocks resist cracks, dampness, and erosion. This reduces the frequency of repairs, saving resources and costs over decades of use.

c. Circular Economy Ready

Made from natural clay, it can be recycled back into the soil or reused in new construction at the end of a building’s life, ensuring it leaves no harmful footprint.

d. Natural Thermal Insulation

The hollow design of Ecotherm blocks enhances thermal efficiency. Buildings stay cooler in summer and warmer in winter, reducing the need for artificial heating and cooling, cutting energy consumption and lowering carbon emissions.

e. Healthier Indoor Environment

Ecotherm regulates humidity naturally, preventing mould growth and dampness. This ensures better indoor air quality, supporting both comfort and health for occupants.

f. Low-Carbon Manufacturing

Produced using natural clay with efficient firing technology, Ecotherm avoids the high carbon footprint associated with energy-intensive materials. Local sourcing further reduces transport emissions.

By embodying the best of both categories, Natural Materials for their eco-friendly origin and Innovative Composites for their engineered performance, Ecotherm represents a new generation of sustainable construction materials.

Upgrade Your Walls with Cladding Tiles

Discover durable and stylish clay cladding tiles that enhance both interiors and exteriors. Add strength, insulation, and timeless design to your projects.

Conclusion: Building a Sustainable Future with PCP

The story of sustainable construction is not only about materials, but about vision. Each choice from natural building materials like clay to innovative hybrids such as Ecotherm Hollow Clay Blocks, reflects how we balance tradition with progress. The industry is no longer asking if sustainable building materials are necessary; it is asking how quickly we can adopt them.

Our commitment has also been recognized globally, PCP is among the select innovators supported by the HCL Climaforce Fund, a testament to Ecotherm’s role in addressing climate challenges through sustainable construction practices and resource-efficient materials.

As cities expand and climate challenges grow, the path forward lies in materials that conserve energy, reduce waste, and last for generations. By combining natural wisdom with engineered innovation, PCP is shaping a construction future that is resilient, resource-efficient, and globally recognized for its contribution to sustainability.

Choosing Ecotherm isn’t just about selecting a walling material, it’s about investing in a future where every building tells a story of responsibility, efficiency, and care for the planet through the power of eco-friendly clay blocks.

Frequently Asked Questions

Sustainable building materials are those that reduce environmental impact while enhancing durability and efficiency. They are low-carbon, energy-efficient, recyclable, and designed to promote healthier, climate-resilient spaces.

Clay is abundant, natural, and recyclable. Ecotherm Hollow Clay Blocks take this further by offering thermal insulation, durability, and indoor comfort, making them both eco-friendly and performance-driven.

The hollow design traps air pockets, providing natural insulation. This reduces the need for artificial heating and cooling, cutting down on energy bills while lowering the building’s carbon footprint.

Unlike solid bricks, Ecotherm blocks are engineered for sustainability. They offer better insulation, lighter weight, reduced carbon production, and enhanced durability, all while maintaining structural strength.

Yes. Ecotherm has been recognized by the HCL Climaforce Fund as “the most advanced sustainable thermal insulating clay product in the world,” a validation of its innovation and sustainability credentials on the global stage.

Absolutely. Ecotherm Hollow Clay Blocks are versatile and suitable for a wide range of projects from energy-efficient homes to large-scale commercial or institutional buildings.

Alongside Ecotherm, we offer Cladding Tiles for energy-efficient façades and Load-Bearing Clay Walls that reduce dependence on concrete and steel. Together, these create a holistic sustainable building system.

By improving insulation, reducing energy consumption, and lasting longer with minimal maintenance, Ecotherm lowers both operational and replacement costs, a win for both the environment and your budget.

Author

-

With over 30 years of hands-on experience in manufacturing, I specialize in scaling operations, enhancing efficiency, and driving innovation across the heavy clay and textile industries.

I currently serve as Chief Operating Officer at Prayag Clay Products Limited, a heritage company founded in 1937. With the combined experience and efforts we have expanded beyond traditional brickmaking to produce advanced heavy clay blocks and exposed brick solutions, including state-of-the-art handmade exposed bricks for the UK, EU, Australian, and New Zealand markets. Most recently, we launched handmade clay roofing tiles, setting a new benchmark for quality and performance in the exposed roofing tile industry.

Previously, I was Managing Director of Egyptian Greek for Clay Bricks and Tiles and General Manager at BEAK S.A. in Komotini, Greece. There, I spearheaded initiatives in technical management, sales, and productivity—boosting roofing tile production by 200% and more than doubling brick output without major new equipment investments. These operational improvements delivered a 230% increase in annual revenue.

Earlier in my career, I entered the Turkish textile sector with FAROFIL, where I built strong partnerships with spinning mills, optimized pricing and quality, streamlined logistics, and strengthened team development. My professional journey began at OTTO Spinning Mills in Alexandroupolis, Greece, where I spent more than a decade as Technical Manager and Mechanical Engineer, overseeing three spinning units specializing in combed yarns and blends.